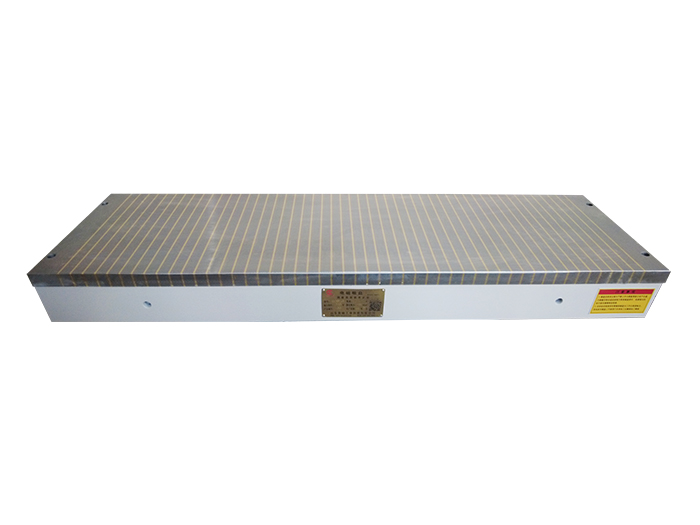

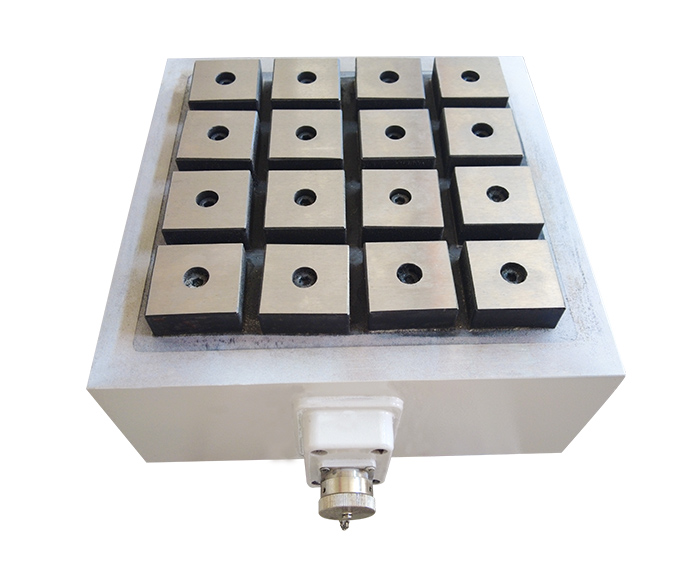

The permanent magnetic chuck is designed based on the principles of magnetic flux continuity and magnetic field superposition. The magnetic circuit of the permanent magnet suction cup is designed as multiple magnetic systems, and through the relative motion of the magnetic systems, the magnetic field strength on the working magnetic pole surface is added or cancelled, thereby achieving the purpose of suction and unloading.

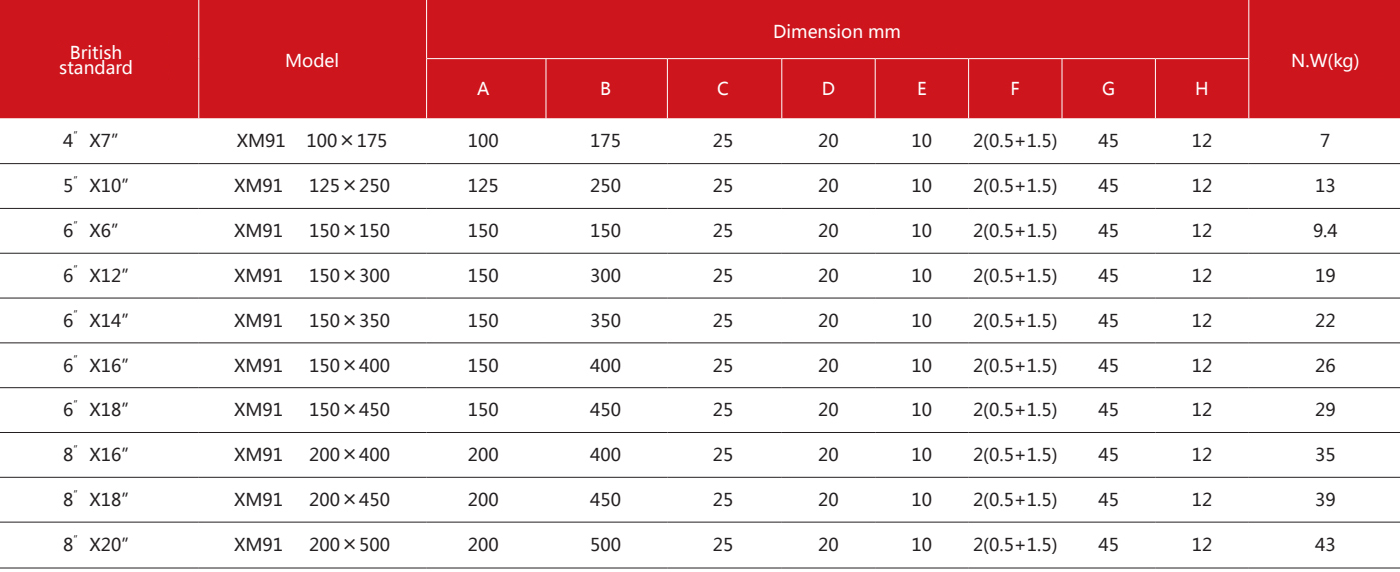

Technical parameters:Production can be customized according to user needs.

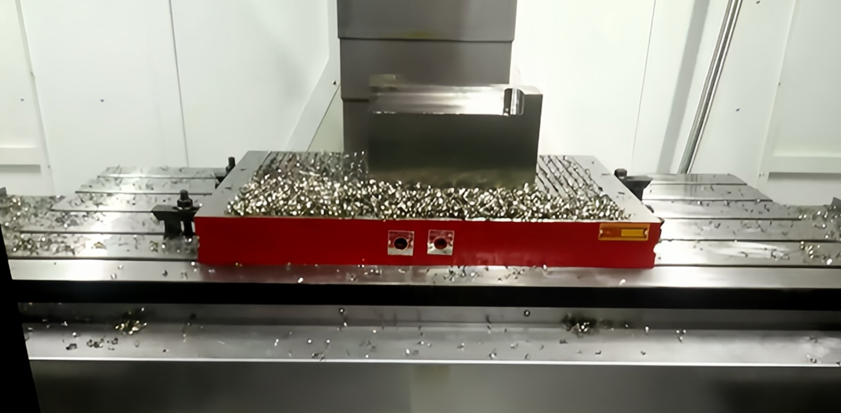

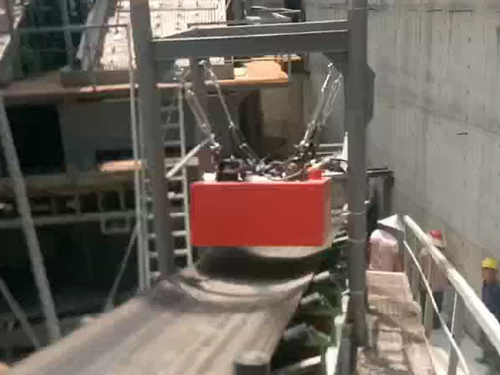

Application scope:Suitable for metal cutting processing, commonly used in mechanical processing equipment such as CNC machining centers, CNC engraving and milling machines, grinders, etc.

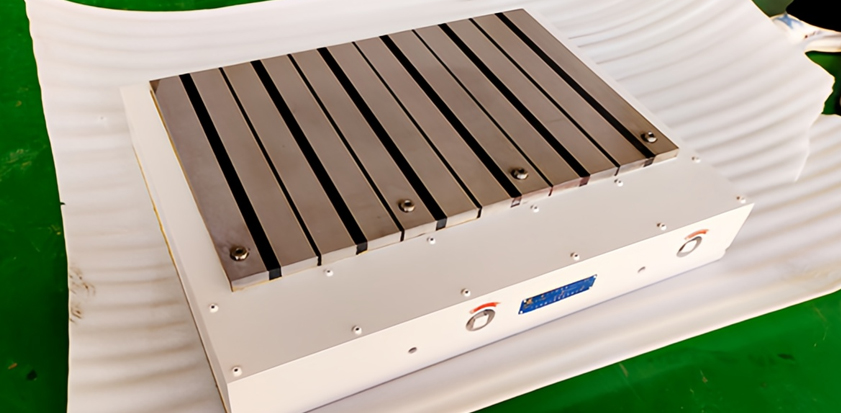

Product features:Uniform magnetic force, high precision, simple operation, precise structure.

Product selling point:The disk does not require power and will not generate heat even after prolonged use. The precision of the disk itself is extremely high, which fully guarantees the precision of the machined parts. Since no power supply is needed to adsorb the workpiece, even if the power is cut suddenly, the workpiece will not move Congee, which can avoid unnecessary losses.

info@lucimagnet.com

info@lucimagnet.com