01

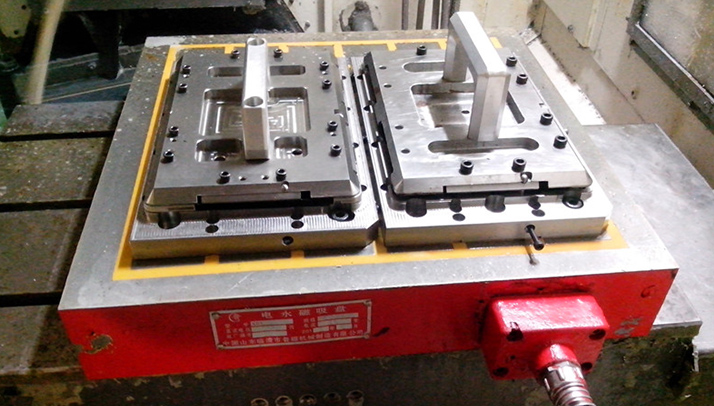

High Efficiency

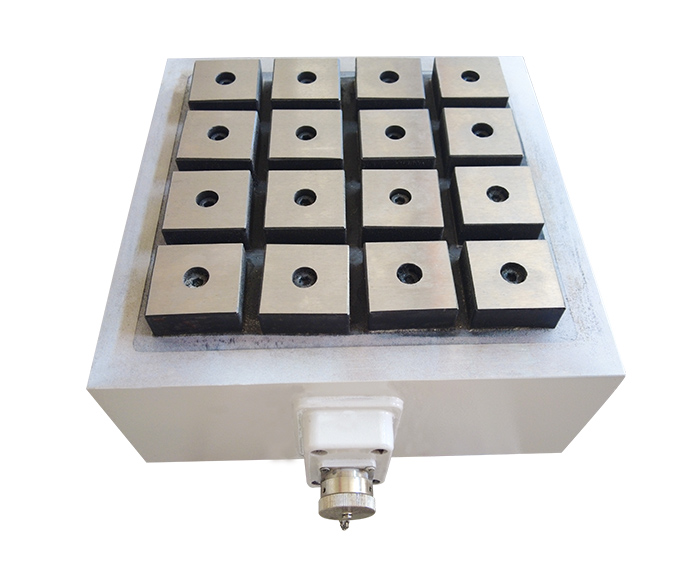

Used in combination with magnetic conducting blocks, the cutting tools can move freely during processing. Five-sided processing, drilling, tapping, milling and cleaning grooves, and forming processing can be completed at one time, greatly improving work efficiency and reducing the repeated positioning tolerance to meet the accuracy requirements.

02

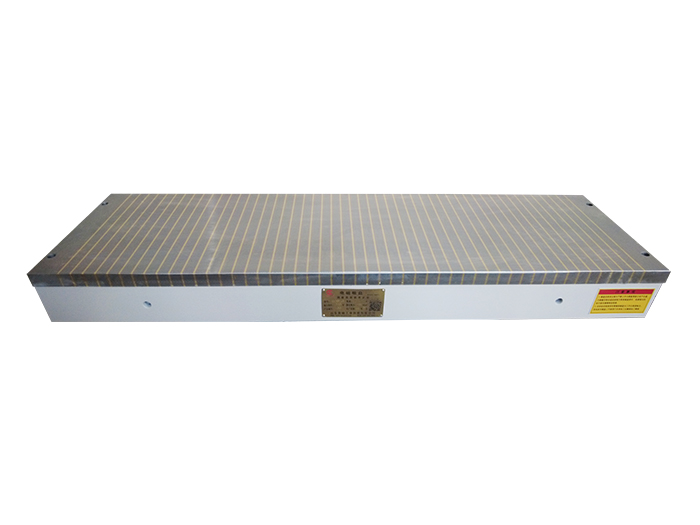

Simple and Quick Operation

With just one simple button, the clamping or release of workpieces can be independently completed within 0.6 - 3 seconds. One clamping can completely realize five-sided processing. When releasing workpieces, demagnetization is automatic. Medium and low carbon steel materials can achieve zero residual magnetism without the need to use a demagnetization device.

03

Maintenance-free and Environmentally Friendly

Electric permanent magnetic chucks are corrosion-resistant, resistant to mechanical impact, have no moving parts inside, no heat generation phenomenon, no wearing and consumable parts, require no maintenance, and the whole system has no leakage and no pollution.

info@lucimagnet.com

info@lucimagnet.com