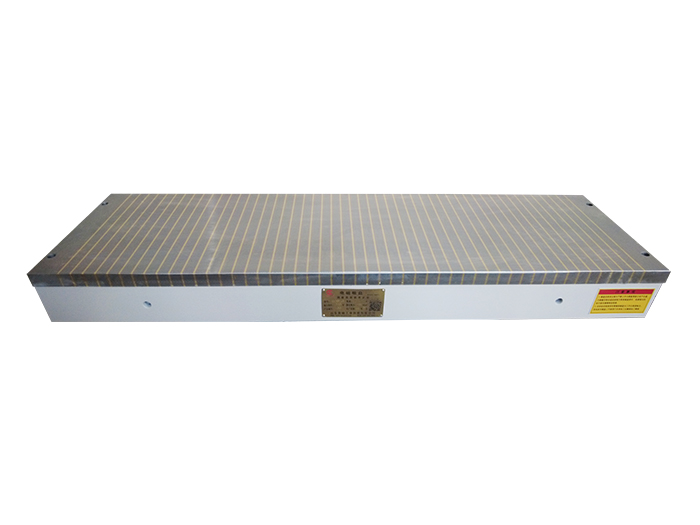

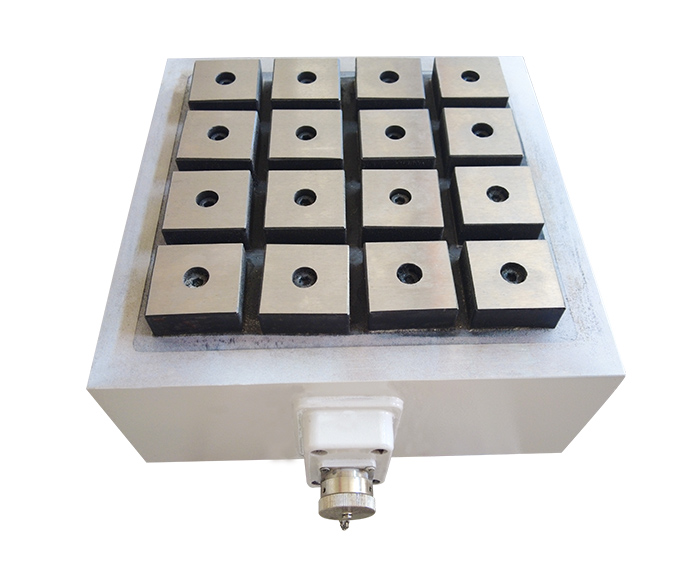

Magnetic chucks have been playing a very important role as magnetic clamping tools for machining. The development of magnetic chucks has experienced three generations of electromagnetic chucks, permanent magnet chucks and electric permanent magnet chuck.

After the 1980s, with the emergence of high-performance neodymium-iron-boron (NdFeB) rare-earth materials, it has become a trend to utilize the NdFeB permanent magnet material to develop magnetic tools, which has greatly facilitated the development and application of electric permanent magnet chucks.

Electric permanent magnetic chucks as electromagnetic chucks, permanent magnetic chucks upgraded products, has been widely popular in Europe and the United States machinery manufacturing industry, become the standard configuration of high-end machine tools.

info@lucimagnet.com

info@lucimagnet.com