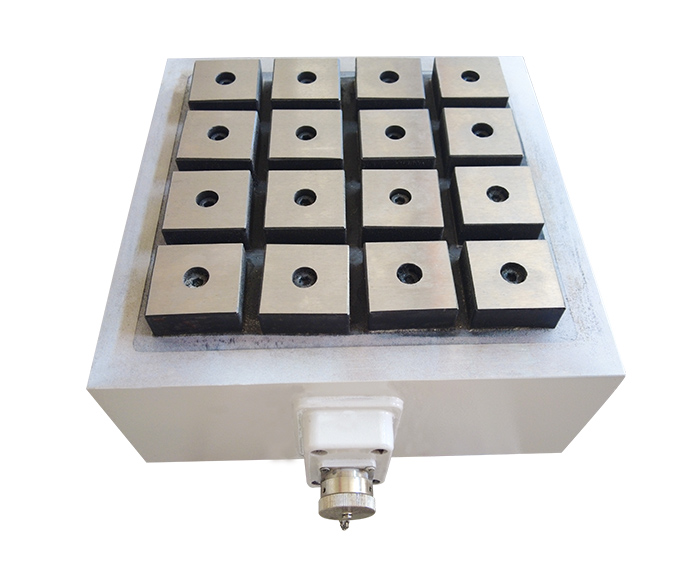

Product Introduction:

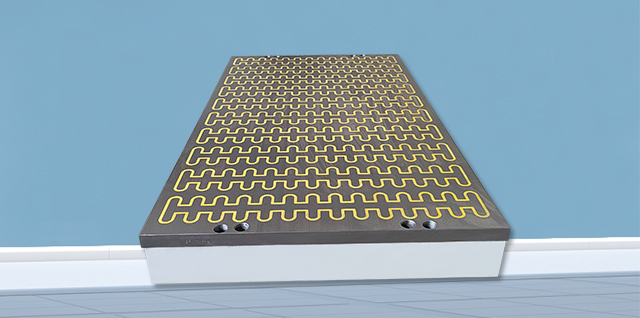

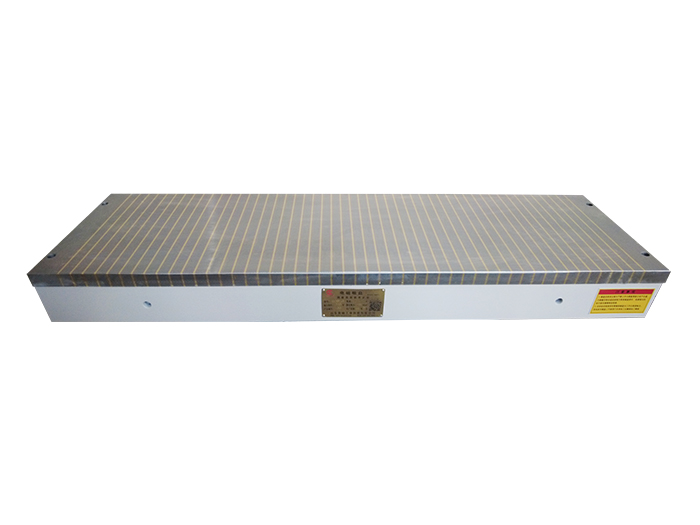

An electromagnetic chuck is a machine tool accessory that utilizes electromagnetic principles. By energizing internal coils to generate magnetic force, it securely holds workpieces in contact with its

magnetic-conductive surface. When the coils are de-energized, the magnetic force dissipates, allowing the workpiece to be removed.

Technical Parameters: Customizable per user requirements

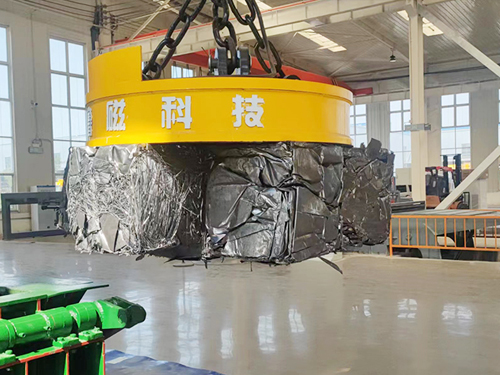

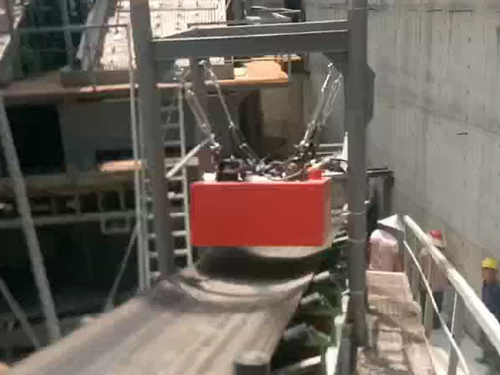

Application Scope:Used in general machinery manufacturing, automotive, shipyards/docks, metallurgy, ports/logistics, warehousing centers, and recycling industries. Suitable for holding magnetic materials during medium-intensity grinding operations on rectangular table surface grinders, circular table surface grinders, knife grinders, gantry milling machines, and gantry planers.

Product Features: Uniform magnetic force, stable precision, accurate positioning, minimal thermal deformation

Key Selling Points: Capable of holding both large and small workpieces; high rigi

Technical parameters:Customizable per user requirements

Application scope:Used in general machinery manufacturing, automotive, shipyards/docks, metallurgy, ports/logistics, warehousing centers, and recycling industries. Suitable for holding magnetic materials during medium-intensity grinding operations on rectangular table surface grinders, circular table surface grinders, knife grinders, gantry milling machines, and gantry planers.

Product features:Uniform magnetic force, stable precision, accurate positioning, minimal thermal deformation

Product selling point: Capable of holding both large and small workpieces; high rigidity, stable precision, extremely low thermal deformation; unique coil design ensures exceptionally uniform magnetic force distribution.

info@lucimagnet.com

info@lucimagnet.com