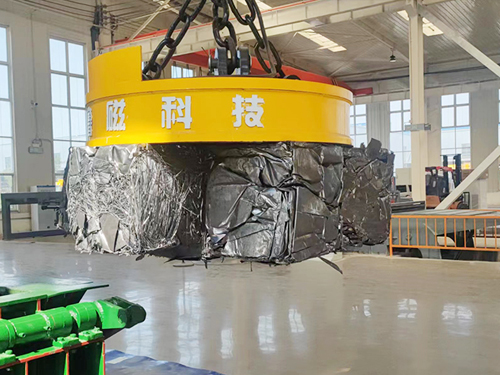

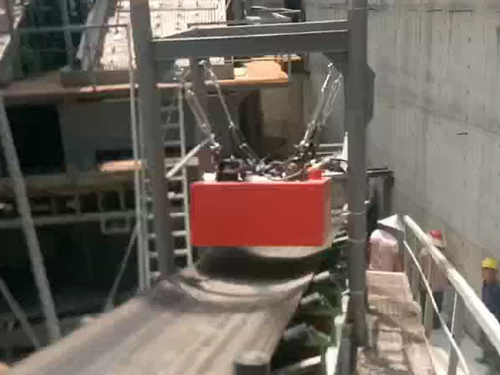

Electro Permanent Magnetic Lifter is designed specifically for lifting medium-thick and wide-thick plates. Considering the possibility of bending and deformation during the lifting of long steel plates, which may affect safe lifting, we usually use multiple gantry cranes when lifting steel plates. We will choose different specifications of lifting electro permanent magnets based on the range of steel plate specifications (length, width, thickness) and the lifting capacity of the crane.

During joint lifting, the following measures should be implemented: Firstly, a special adaptive mechanism is used for the connection between the beam and the lifting electric permanent magnet. Secondly, for steel plates with a lifting thickness of less than 20mm, small-tonnage and multiple lifting points are arranged, and two arrangements are made in the width direction of the steel plate to minimize the impact of plate unevenness, reduce the working air gap, and enhance suction. Thirdly, magnetic contr

Technical parameters:Customizable according to clients' needs.

Application scope:Dock ships, metallurgical industry, automotive industry, ports, warehousing centers, general machinery manufacturing, renewable resources.

Product features:No loss of magnetism in case of power outage, saving 95% of electrical energy, and maintaining strong magnetic force without attenuation.

Product selling point:This lifting device can select lifting electric permanent magnet lifting devices with different lifting tonnages according to the specification range of steel plates (length, width, thickness) and the lifting tonnage of the crane. Multiple combination modes can be used for joint lifting (which can be controlled by grouping).

info@lucimagnet.com

info@lucimagnet.com