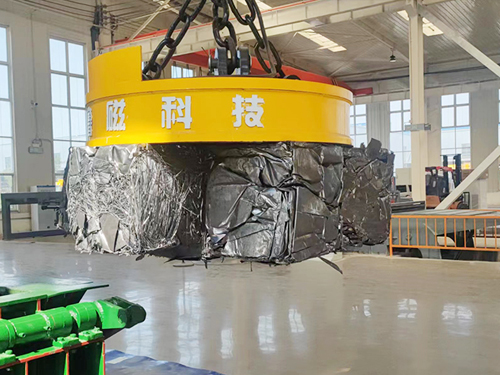

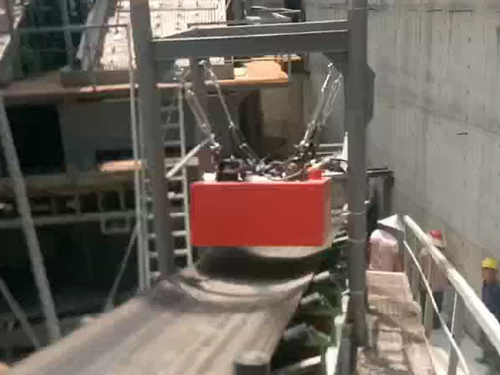

The permanent magnet lifter is mainly used to adsorb workpieces made of steel plates or cylindrical ferromagnetic materials. It features a lightweight structure, convenient operation, strong adsorption force, and high safety and reliability, which helps improve the working conditions of loading, unloading, and handling operations and increase labor productivity.

Technical parameters:Customized production can be carried out according to user requirements.

Application scope:It is mainly used in shipyards, riveting and welding factories, structural component factories, warehouses, workshops, freight yards, etc., and is used in conjunction with various lifting equipment to adsorb plate-shaped ferromagnetic materials or workpieces. It can not only lift and transport steel plates, ingots, and section steels but also be combined in multiple units to lift ferromagnetic workpieces that are wide and long.

Product features:Lightweight structure, convenient operation, strong adsorption force, and high safety and reliability.

Product selling point: It is mainly used to adsorb workpieces made of steel plates or cylindrical ferromagnetic materials and helps improve the working conditions of loading and unloading as well as handling operations and increase labor productivity.

info@lucimagnet.com

info@lucimagnet.com