Product Features

01

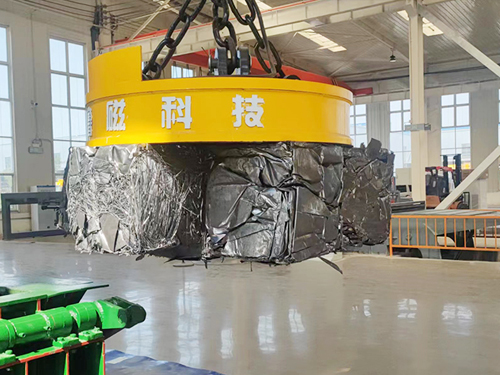

Mainly used to remove iron in powder, granular or block non-magnetic materials.

02

Computer simulation design, large magnetic penetration depth, strong suction.

04

Low power supply, low power consumption, low temperature rise, low failure rate.

03

Good sealing performance, dustproof, sun protection, corrosion resistance.

Product Advantages

Fine Iion RemovalMainly used to remove iron in powder, granular or block non-magnetic materials, due to the raw materials in the process of processing inevitably mixed with some small iron, sometimes mixed with a small amount of iron titanium minerals, through computer simulation design, magnetic penetration depth, strong suction, iron removal ability more fine.

High Magnetic Field, High GradientIts internal unique magnetic circuit design, so that it has strong suction, deep magnetic penetration and other characteristics. With axial fan strong near air cooling, large air volume, fast heat dissipation, low temperature rise, to ensure that the iron remover long-term work without fault, the application of better materials, so that the iron remover magnetic field strength to achieve the best, the gradient is getting larger and larger.

Energy Saving AspectIt is cast with electrician special resin, fully sealed structure, and has the characteristics of maintenance-free and strong magnetic force. It can still work reliably and continuously in extremely harsh environment, which can not only improve the grade of raw materials and purify, but also be used for the recovery of ferromagnetic substances.

Low MaintenanceThe magnetic circuit design of the iron remover body is reasonable, the magnetic field strength is high, and the magnetic penetration depth is large, so it is suitable for iron removal where the material layer is thick, and the reliability is strong and the maintenance is less.

Applications

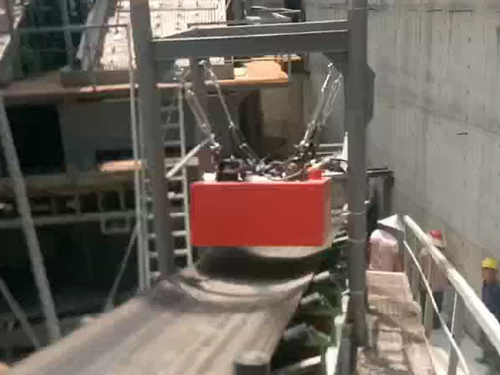

Widely used in industries such as power, mining, metallurgy, building materials, coal preparation, chemical industry, etc.

Electricity

Mining

Metallurgy

Building materials

Coal preparation

Chemical industry

Services Support

Selection service

30 + engineers 1V1 to assist the user selection, with the customer to issue products and technical solutions, and provide test grinding workpiece and grinding process.

Personalized customization

According to the material and workpiece size, weight, shap, providing personalized customization, provide intelligent handling and a full set of clamping and lifting solutions.

After-sales service

Provide free video guidance, you can also choose to pay for door-to-door after-sales service; provide original spare parts.

info@lucimagnet.com

info@lucimagnet.com