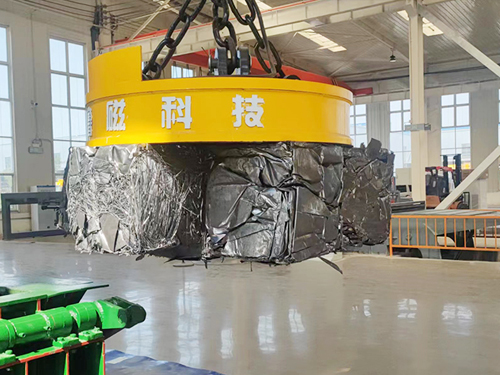

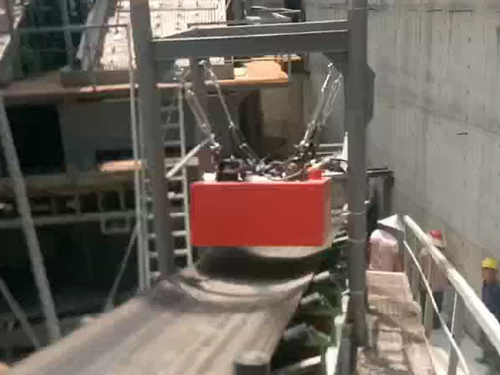

Iron remover is an electromagnetic device used to remove iron components from non-magnetic materials. It is composed of magnetic system, shell and other parts, and is an environmentally friendly, efficient and energy-saving iron removal equipment. Generally installed at the head or middle of a belt conveyor, the strong magnetic force generated by electricity will suck out the iron pieces mixed in the material and throw them out by the iron unloading belt, achieving the purpose of cleaning and effectively preventing the longitudinal scratching of the conveyor belt, protecting the normal operation of crushers, grinders, etc.

Technical parameters:Production can be customized according to user needs.

Application scope:Widely used in industries such as power, mining, metallurgy, building materials, coal preparation, chemical industry, etc.

Product features:Fault free continuous operation in harsh environments, low failure rate, large magnetic penetration depth, strong suction force.

Product selling point:A set of automatic iron unloading mechanism has been added to the iron remover, which automatically throws out the ferromagnetic substances adsorbed on the iron remover through the automatic iron unloading mechanism during operation.

info@lucimagnet.com

info@lucimagnet.com