Product Advantages

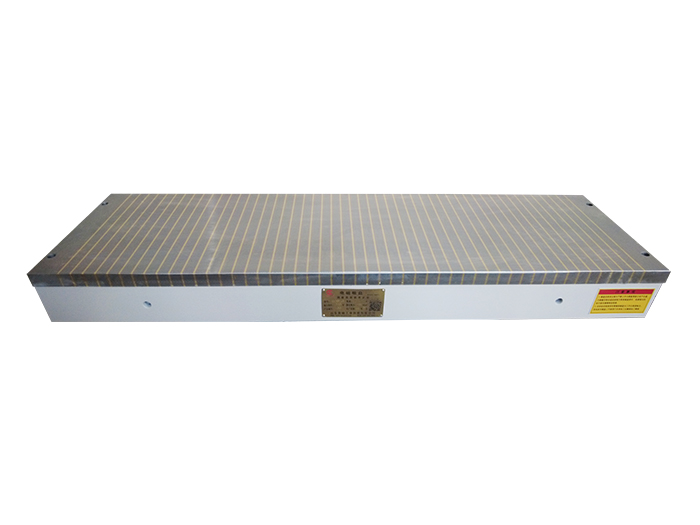

Safe and PowerfulThe electric permanent magnetic rapid mold change system does not require electrical energy during operation. It relies solely on permanent magnetic suction to hold workpieces and molds. It avoids the danger of mold falling off in case of sudden power failure in traditional rapid mold change systems. The suction force of the chuck can be as high as 16KG/cm² or more, which remains constant over time and has extremely high safety.

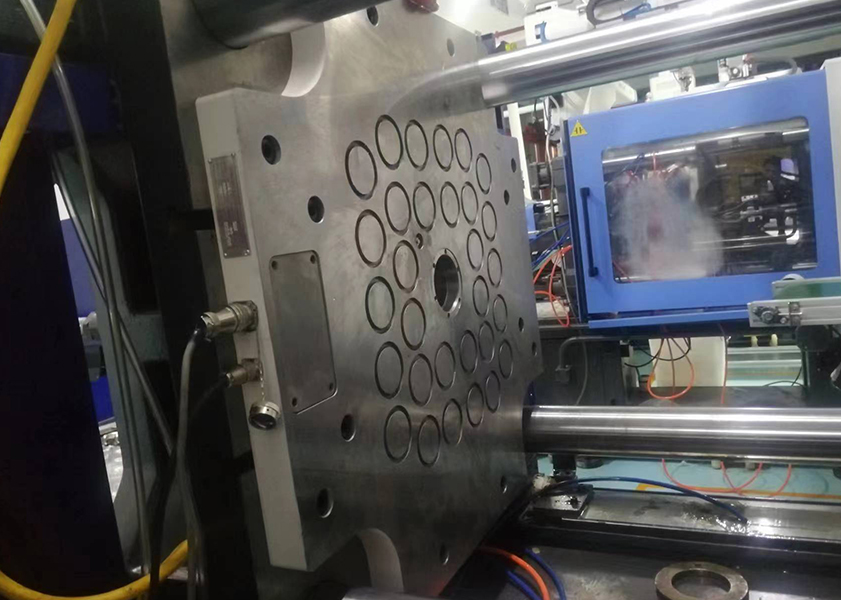

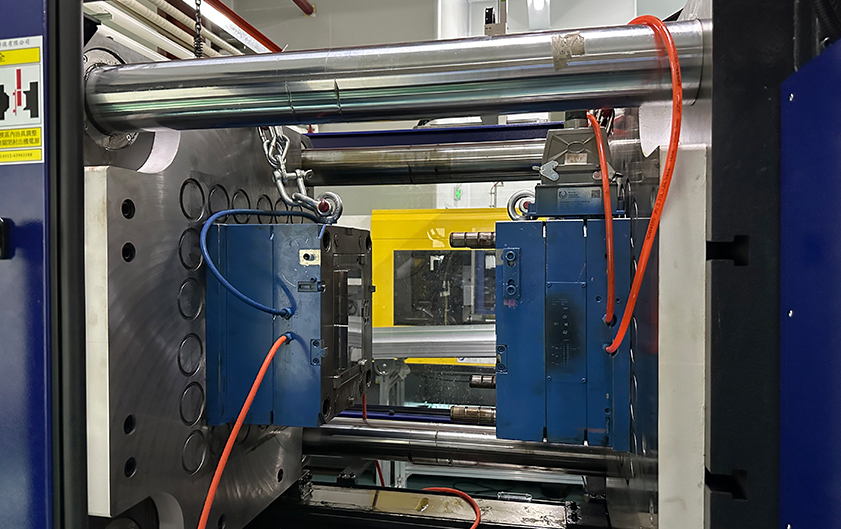

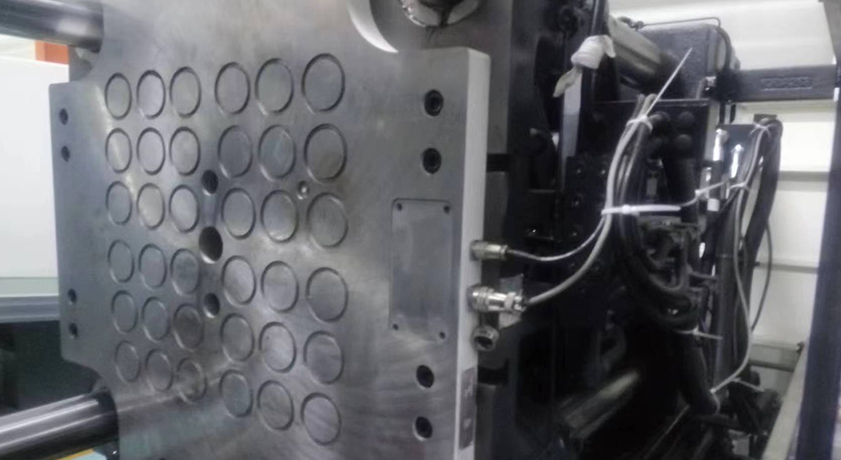

Fast and EfficientThe electric permanent magnetic rapid mold change system used for rapid mold changing and clamping systems can greatly improve the mold changing efficiency. Generally, the mold changing and clamping operations for injection molding machines only take 3 minutes, and the mold changing time for extra-large molds is shortened from over 2 hours to 10 minutes. The clamping force of the electric permanent magnetic chuck template is evenly distributed on the entire contact surface between the mold and the magnetic disk, leaving no "cavity" without force on the back of the mold, better ensuring the mold clamping accuracy, greatly reducing mold wear, and improving the service life of the mold; reducing production inventory and raw material waste! It can ensure normal operation for molds of any weight.

Space-saving and DurableThe electric permanent magnetic chuck rapid mold change system can save a lot of space as it does not use pressure plates and other pneumatic or hydraulic components, making all the peripheral equipment of the mold more convenient for maintenance and operation. The clamping force of the electric permanent magnetic chuck template is evenly distributed on the entire contact surface between the mold and the chuck, and the magnetic depth is within 10mm, preventing stress deformation of the mold. There is no force "cavity" on the back of the mold, better ensuring the mold clamping accuracy, greatly reducing mold wear, and improving the service life of the mold.

Almost Zero Operating and Maintenance CostsThere is no need for additional costs related to screws, nuts, pressure plates, special tools, oil drainage, etc. There is no need to maintain the templates of injection molding machines and electric permanent magnetic chuck templates. Electrical energy is only needed for a few seconds when changing molds, and no energy consumption is required at other times.

Simple to OperateThe operation panel instructions are clear at a glance, and the operation is simple and fast. Any non-professional can master the operation essentials within 1 minute and can operate independently to safely and quickly change the molds. During the replacement of large molds, the number of operators can be reduced, greatly reducing labor costs and the work intensity of employees.

Comparison between Electric Permanent Magnetic Rapid Mold Change and Traditional Mold Change Tools

Electric Permanent Magnetic Rapid Mold ChangeEasy to Install

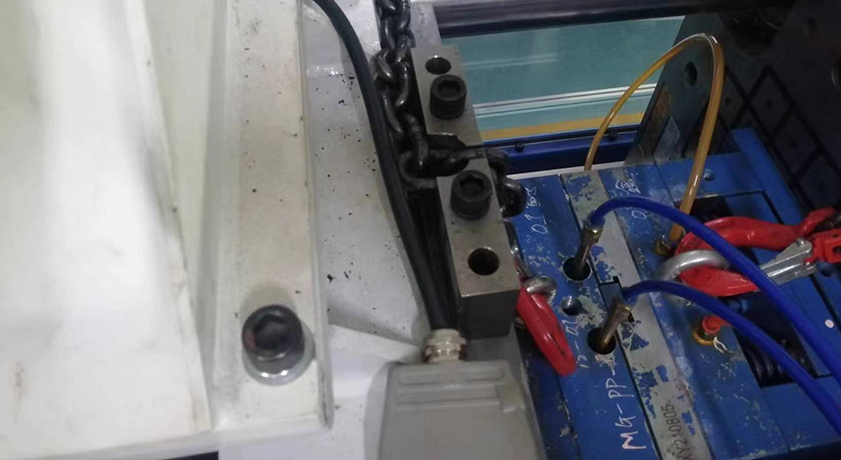

Fix the chuck template on the threaded holes or T-slots on the back plate of the injection molding machine without any adjustment or correction. Generally, the mold clamping operation for injection molding machines only takes 3 minutes.

High Safety Performance

It only uses electrical energy during the magnetization and demagnetization processes within 1 - 2 seconds and does not use any energy during operation. It is safe, powerful, and efficient.

High-efficiency Production

The clamping force is uniform, preventing stress deformation of the mold, better ensuring the mold clamping accuracy, and greatly improving the quality consistency of injection molded parts.

Durable

It is a one-time investment, without the need for additional costs for fixtures, pneumatic components, hydraulic oil, etc. There is no need to replace parts regularly.

Traditional Mold Change ToolsComplicated Installation

Traditional mold installation is complicated, time-consuming, and labor-intensive, and there are significant safety hazards.

High Safety Hazards

There are many electrical, hydraulic, and pneumatic circuits and accumulators in traditional mechanical, hydraulic, and pneumatic fixture systems, which are prone to oil and gas leakage and fatigue damage of clamping bolts. There are high safety hazards.

Low Efficiency

The mold changing time is long and complicated, seriously affecting production efficiency and machine utilization rate. The efficiency is low.

High Wear and Tear

There is no clamping force around the back plate of traditional mold change tools. During operation, the mold has large deformation and wear, and the components at the clamping parts are severely worn.

Services Support

Selection service

30 + engineers 1V1 to assist the user selection, with the customer to issue products and technical solutions, and provide test grinding workpiece and grinding process.

Personalized customization

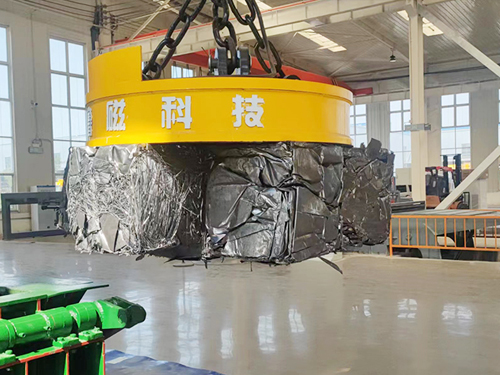

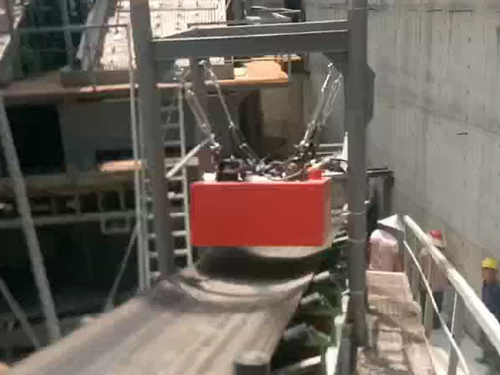

According to the material and workpiece size, weight, shap, providing personalized customization, provide intelligent handling and a full set of clamping and lifting solutions.

After-sales service

Provide free video guidance, you can also choose to pay for door-to-door after-sales service; provide original spare parts.

info@lucimagnet.com

info@lucimagnet.com