A demagnetizer is a device used to eliminate residual magnetism caused by mechanical processing. It generates magnetic field lines from an electromagnetic coil and directly or indirectly interferes with the magnetic properties of the original workpiece through the magnetic field lines to achieve demagnetization of the workpiece.

The main demagnetizers include platform demagnetizers, frame demagnetizers, etc. The frame demagnetizer mainly passes through the workpiece inside the coil to achieve demagnetization effect by cutting the residual magnetism of the workpiece through the magnetic field lines.

The demagnetizer requires alternating current to magnetize the coil.

Technical parameters:Production can be customized according to user needs.

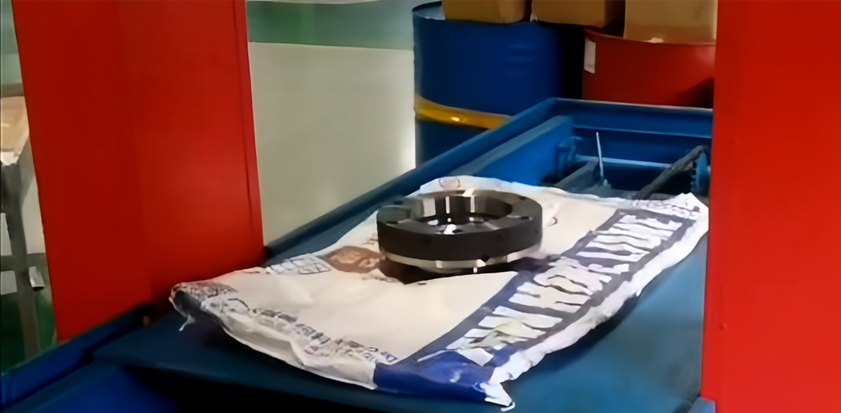

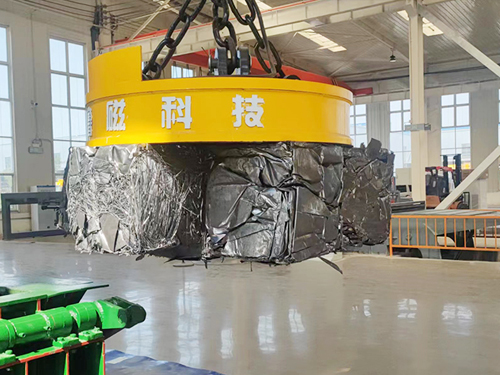

Application scope:Widely used for demagnetization of magnetic products, workpieces, and components (such as magnetic metal steel parts, steel pipes, bearings, gears, molds, and automotive parts) after mechanical processing.

Product features:High precision, high speed, low magnetic field residue, strong controllability, low cost.

Product selling point:The demagnetization machine coil is designed through electromagnetic induction principle to optimize the magnetic circuit. It uses full wave current waveform demagnetization, which has no interference to the power grid, low power consumption, and strong anti-interference ability. The design concept is based on the actual requirements of the factory, using gradient magnetic field design, good demagnetization effect, reasonable selection of component parameters, high reliability, and good stability.

info@lucimagnet.com

info@lucimagnet.com