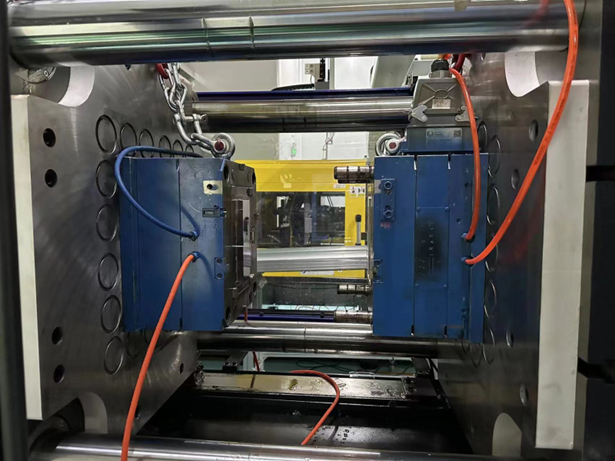

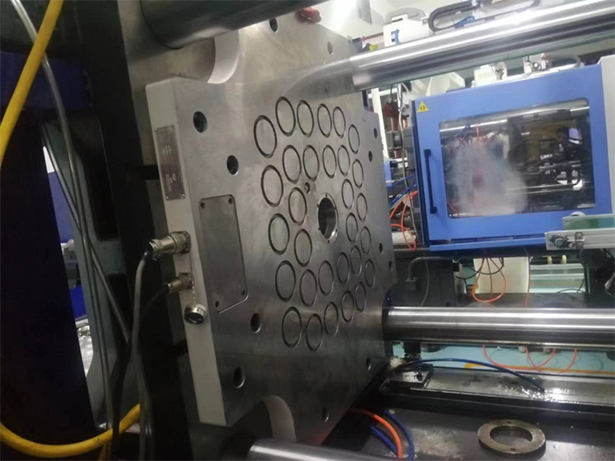

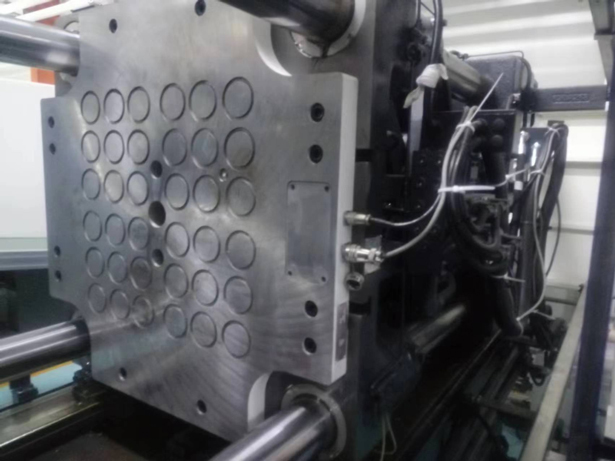

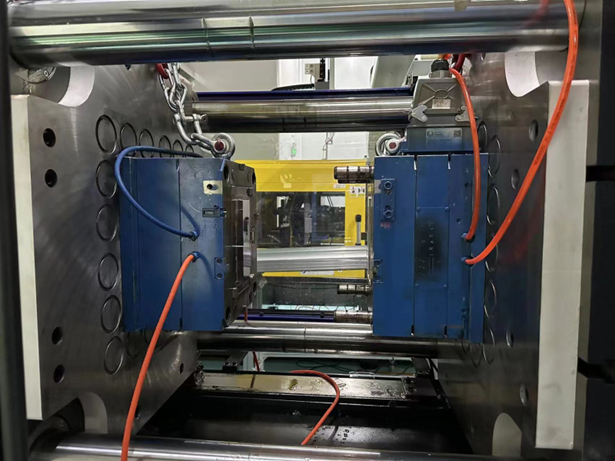

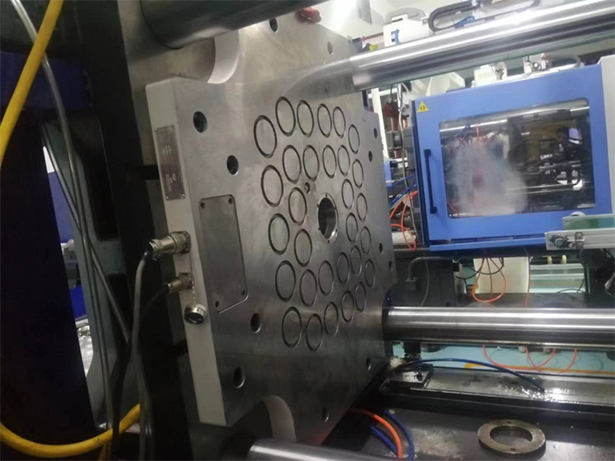

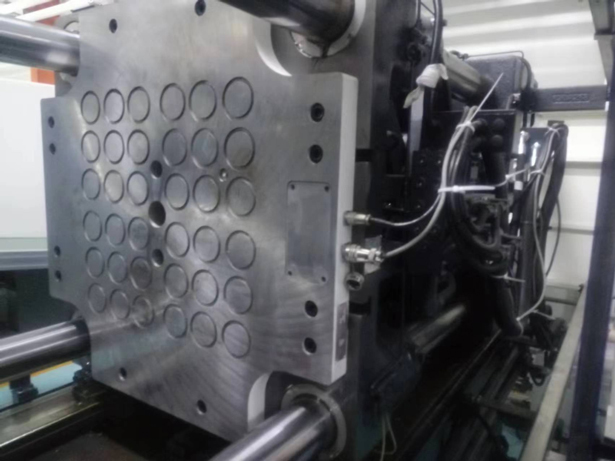

In the rapidly developing manufacturing industry, the magnetic rapid mold changing system of injection molding machines has brought revolutionary improvements to mold replacement with its innovative technology. This system applies the principle of magnetism, which enables the mold to be firmly attached to the machine tool in an instant, greatly improving the speed and efficiency of mold replacement.

When it comes to improving production efficiency, the magnetic mold changing system reduces the tedious steps of tightening and disassembling screws, shortening the mold changing process to within a few minutes and greatly reducing machine idle time. This directly improves the efficiency of injection molding machines and enables the smooth execution of compact production plans.

In terms of product quality, the precise positioning function of the system ensures that every mold replacement can achieve high-precision alignment, reducing the production of defective products due to improper mold installation, and ensuring the uniformity and reliability of the product.

From the perspective of operational safety, this technology reduces manual intervention, alleviates the burden on operators, lowers risks and potential injuries in work, and provides a safer working environment for operators.

In terms of energy efficiency, as machines do not need to be stopped, additional energy consumption is reduced, which is in line with the modern manufacturing industry's pursuit of environmental protection and energy conservation.

Ultimately, the ease of use and efficiency of the magnetic mold changing system have helped companies reduce labor and time costs, further enhancing their market competitiveness.

Overall, the magnetic rapid mold changing system of injection molding machines not only improves production efficiency, but also ensures product quality and operational safety. At the same time, it plays a significant role in energy conservation, cost reduction, and efficiency improvement, and is an innovative leap in the field of injection molding manufacturing.

Luci Magnet specializes in the research and manufacturing of heavy-duty industrial magnets for 50+ years. Our core product lineup includes magnetic lifters, magnetic chucks, quick die change systems, magnetic grippers,magnetic separators, and demagnetizers.

info@lucimagnet.com

info@lucimagnet.com